Billy Bunter of Greyfriars School

Billy Bunter – larger than life !

I say you fellows do listen to a chap for a minute …  So began many a tale of a hero of mine good old William George Bunter of Greyfriars School.

So began many a tale of a hero of mine good old William George Bunter of Greyfriars School.

I stumbled upon Billy Bunter quite by chance when I accompanied my mother to the local library one balmy summers evening many, many years ago, when summers were summers and winters were winters and I was still in short trousers (only the other day then I hear some wag remark !). Actually I would have been about nine or ten years old, in those days you didn’t wear long trousers until you went to senior school and then only in the second form. As there were no ‘Just William’ books on the library shelves my eye was caught by the title ‘Billy Bunter of Greyfriars School‘ and as it happens having read that one book I just couldn’t wait to get back the following fortnight for yet another dose of Billy (sounds painful, can you get anything for it ? ).

Billy Bunter or William George Bunter to give him his full name was the invention of Charles Hamilton and written under his pen name of Frank Richards. The schoolboy character originally featured in stories set at Greyfriars School in the boys weekly story paper ‘The Magnet’. First published in 1908 The Magnet was to continue through to 1940 with Bunter appearing in almost all the publications with Frank Richards writing the majority, but not all of the stories, although his pen name was applied to them all. Sadly the Second World War saw an end to The Magnet due to paper shortages.

Billy Bunter may have disappeared forever had it not been for publisher Charles Skilton who commissioned Charles Hamilton to write a series of books around Bunters adventures and those of the ‘Famous Five’ (no not the Enid Blyton ones these were the original ones, Wharton, Cherry, Bull, Newton and Hurree Jamset Ram Singh or Inky to his friends) at a fictitious private school in Kent …… Greyfriars.

been for publisher Charles Skilton who commissioned Charles Hamilton to write a series of books around Bunters adventures and those of the ‘Famous Five’ (no not the Enid Blyton ones these were the original ones, Wharton, Cherry, Bull, Newton and Hurree Jamset Ram Singh or Inky to his friends) at a fictitious private school in Kent …… Greyfriars.

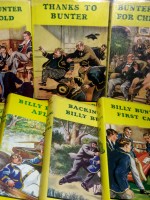

38 hardback books were written in total and although all were produced with various coloured boards one thing remained constant, they all came with the distinctive yellow background dust jacket. Initially published by Skilton and then later by Cassells the first novel, ‘Billy Bunter of Greyfriars School’ saw light of day in 1947 and began a series which continued for the rest of Hamiltons life and certainly gave me enjoyment throughout mine. I will limit this post from the perspective of those 38 novels as the subject of Hamilton, Bunter, Greyfriars et all is just too large as to do otherwise but is a subject I will no doubt return to.

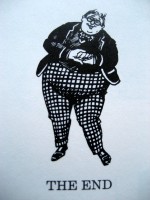

But what is it that endears one to the Billy Bunter stories ? Certainly Bunter is a most unlikely hero, addressed by his form master Mr. Quelch in one episode Bunter is told, ‘You are lazy, idle, greedy, undutiful, slack in class and slack at games – in no respect whatever a credit to this school.’ He goes even further, ‘Your stupidity I can excuse – I can make allowance for that. But your idleness – your slackness – your incorrigible untruthfulness – these are faults you could amend, if you chose. You are a disgrace to your form, Bunter’. Bunters response as always just makes you smile or indeed laugh out loud, ‘Not me Sir ! perhapse you are mixing me up with some other fellow sir, perhaps your thinking of Wharton or Cherry … -or-or Nugent .. -or Toddy !’ … Priceless, for Bunter is unable to see his own faults and anyone who points them out is regarded as a Beast ! particularly his form master Quelch who Bunter insists is prejudice against him. Yet despite all his faults, and in Bunters case they are many, one simply cannot help but feel sympathy for the character Charles Hamilton has created, however turn the page and read on and inevitably you feel like booting him yourself !

Bunter seems to have two main aims in life,  one is to avoid work of any description indeed he will often spend twice as long trying to avoid it as doing it in the first place ! Instead he prefers to laze in a comfy armchair in front of a blazing fire eating a chunk of toffee .. for that is Bunters other concern .. food. By any standards Bunter is big, no lets be honest Bunter is fat, and his thoughts are almost always centred on feeding the inner Bunter. Bunters greediness knows no bounds, sticky buns and cake he can demolish at a sitting but its perhaps jam that has the ability to draw him like a magnet. Despite never having any money himself, although he is always expecting his infamous Postal Order to arrive, Bunter is a master scrounger up and down the Remove of anything from the odd copper or two to a sixpenny piece and in some exceptional cases the odd half-a-crown, anything with which to buy some sticky sweetmeats from the tuck shop and if all else fails he is quite capable of helping himself to comestables from other boys study cupboards ! all without a though for the rightful owner, inevitably Bunter is found out

one is to avoid work of any description indeed he will often spend twice as long trying to avoid it as doing it in the first place ! Instead he prefers to laze in a comfy armchair in front of a blazing fire eating a chunk of toffee .. for that is Bunters other concern .. food. By any standards Bunter is big, no lets be honest Bunter is fat, and his thoughts are almost always centred on feeding the inner Bunter. Bunters greediness knows no bounds, sticky buns and cake he can demolish at a sitting but its perhaps jam that has the ability to draw him like a magnet. Despite never having any money himself, although he is always expecting his infamous Postal Order to arrive, Bunter is a master scrounger up and down the Remove of anything from the odd copper or two to a sixpenny piece and in some exceptional cases the odd half-a-crown, anything with which to buy some sticky sweetmeats from the tuck shop and if all else fails he is quite capable of helping himself to comestables from other boys study cupboards ! all without a though for the rightful owner, inevitably Bunter is found out  whereupon its whops from Quelch – Swipe ! .. ‘Yarooooh’, Swipe ! .. ‘Oh ! Ooooh !’, Swipe, Swipe, SWIPE ! .. ‘ Yow – Ow – WHOOOOOOOP !’ or a booting from his fellow Removites – ‘I- I say, you fellows, Yow-wow, Beasts, Oh-lor’ !’ neither of which has any effect on him except in the short term.

whereupon its whops from Quelch – Swipe ! .. ‘Yarooooh’, Swipe ! .. ‘Oh ! Ooooh !’, Swipe, Swipe, SWIPE ! .. ‘ Yow – Ow – WHOOOOOOOP !’ or a booting from his fellow Removites – ‘I- I say, you fellows, Yow-wow, Beasts, Oh-lor’ !’ neither of which has any effect on him except in the short term.

Bunter has the ability to wander from the truth without knowing that he has, he can repeat the tale that often that in the end he believes that his untruth is in fact a reality. In his opinion Bunter is ‘the goods’, the only decent fellow at Greyfriars and all the others are Beasts ! that is until he needs their help in one of his outrageous schemes which are usually greeted on their inception with Bunter cachinating ‘He-he-he !’. Bunter may be simple but he is cunning, unfortunately for him his schemes always have a habit of coming unstuck but invariably have the habit of turning out all right by the last page.

Apart from his circumference the other feature which made Bunter stand out in the crowd was his thick, round spectacles, which he wore as he was so amazingly short-sighted. These round spectacles gave him the appearance of an owl, hence the chaps often referred to him as the ‘fat owl of the remove’. His writing was appalling, often compared to that of a spider having dipped its legs in the ink pot and crawled across the page. As for his spelling, well lets leave that up to you to decide with a notice which Bunter posted on the wall of the Remove landing :

NOTISS

THE BUNTER PHUND

All my pals in the Remove are hearby rekwested to ralley rownd and help a chap out of a hoal.

THE WEAK’S GOOD KAUSE !

Every fellow willing to help a pal in a bad phix, please stepp into No.7 Studdy, and put something in the bocks on the table. Smorl contribootions thankfully receeved. Shell out your bobbs and tanners and half-crowns.

Sined,

W.G. Bunter.

P.S. Kurrency noats will be welcome.

P.P.S. Koppers not refewsed.

Bunter was rather pleased with that ‘notiss’….. Needless to say Quelch wasn’t !

However beneath all this selfish exterior, when push comes to shove, Bunter does try his best to do the right thing, usually with hilarious results for all concerned. The one person Bunter does care for, apart from himself that is, is his mater, so when all is said and done the chap can’t be all that bad ! … CAN HE ?

.

.

BILLY BUNTER BOOKS FOR SALE

If you are looking for any of the Billy Bunter series of books or any of the Billy Bunters Own series or indeed anything Billy Bunter related please let me know and I will see if we have it in stock.

any Dinky lorry for reference at this point where the cab and chassis form one casting). When this is the case our hero draughtsman comes to our aid and modifies the design such that one of its two sections will now have further parts within it which will slide out sideways so as to allow the casting to be ejected from the mould. (pause for a fanfare of trumpets for the drawing office !).

any Dinky lorry for reference at this point where the cab and chassis form one casting). When this is the case our hero draughtsman comes to our aid and modifies the design such that one of its two sections will now have further parts within it which will slide out sideways so as to allow the casting to be ejected from the mould. (pause for a fanfare of trumpets for the drawing office !). case of the radiator grille, headlights or front and rear bumpers, in others its a colour flash to a rear wing but this now requires the use of a hand spray gun. It also involves the use of model ‘masks’ which will allow the application of the second colour, say aluminium for headlights, being applied where it is needed without contaminating other parts of the model. These hand gun stations are located along a conveyor table fitted with miniature spraying booths and the masks used will vary according to the needs of the particular model. Baking follows again to harden the enamel and then the model is ready for final assembly.

case of the radiator grille, headlights or front and rear bumpers, in others its a colour flash to a rear wing but this now requires the use of a hand spray gun. It also involves the use of model ‘masks’ which will allow the application of the second colour, say aluminium for headlights, being applied where it is needed without contaminating other parts of the model. These hand gun stations are located along a conveyor table fitted with miniature spraying booths and the masks used will vary according to the needs of the particular model. Baking follows again to harden the enamel and then the model is ready for final assembly.

It would appear that the works of Wells-Brimtoy came together under one roof at the ‘Progress Works’, Stirling Road, Walthamstow, E17, sometime after 1938 and continued in its by now established production of tin plate toys, in particular its ‘O’ gauge railway models.

It would appear that the works of Wells-Brimtoy came together under one roof at the ‘Progress Works’, Stirling Road, Walthamstow, E17, sometime after 1938 and continued in its by now established production of tin plate toys, in particular its ‘O’ gauge railway models.

around the corner from Stirling Road lies Blackhorse Lane, which from the early 1900’s was home to several omnibus companies. In 1908 the London General Omnibus Co. (LGOC) took-over the Vanguard Omnibus Co., who were already established on Blackhorse Lane. It was the LGOC who developed the ‘B-type’ omnibus

around the corner from Stirling Road lies Blackhorse Lane, which from the early 1900’s was home to several omnibus companies. In 1908 the London General Omnibus Co. (LGOC) took-over the Vanguard Omnibus Co., who were already established on Blackhorse Lane. It was the LGOC who developed the ‘B-type’ omnibus  which is regarded nowadays as being the first mass produced omnibus. In 1911 it went on to form Associated Equipment Co. Ltd. (A.E.C.) whos later collaboration with London Transport was to see the development of the RT and Routemaster buses. The buses and trolleybuses of Wells-Brimtoy were clearly

which is regarded nowadays as being the first mass produced omnibus. In 1911 it went on to form Associated Equipment Co. Ltd. (A.E.C.) whos later collaboration with London Transport was to see the development of the RT and Routemaster buses. The buses and trolleybuses of Wells-Brimtoy were clearly  meant to represent London Transport vehicles and indeed the double-deck bus was obviously based on the Routemaster.

meant to represent London Transport vehicles and indeed the double-deck bus was obviously based on the Routemaster.

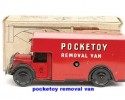

increasing at an alarming rate. W-Brimtoy needed to offset these shortages in raw materials whilst at the same time reducing its production costs and also meeting the massive demand at home for toys following the ending of the war. The result was the ‘Pocketoy’ series of vehicles which W-Brimtoy launched in 1952

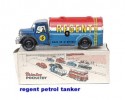

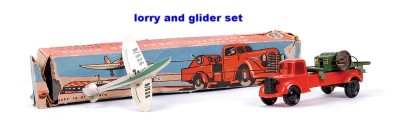

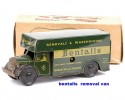

increasing at an alarming rate. W-Brimtoy needed to offset these shortages in raw materials whilst at the same time reducing its production costs and also meeting the massive demand at home for toys following the ending of the war. The result was the ‘Pocketoy’ series of vehicles which W-Brimtoy launched in 1952 which combined the latest plastic moulding methods along with traditional lithographed tinplate. The majority of the Pocketoy range was some 3.5″ in length but larger vehicles were produced and some continued to be produced entirely in tinplate. The majority of this series however did have one thing in common – the

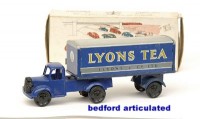

which combined the latest plastic moulding methods along with traditional lithographed tinplate. The majority of the Pocketoy range was some 3.5″ in length but larger vehicles were produced and some continued to be produced entirely in tinplate. The majority of this series however did have one thing in common – the  Bedford truck – which dominated the series throughout its production with a range of colourful plastic cabs and chassis onto which was mounted an array of various tinplate ‘boxes’. Early Pocketoy lorries were based around the Bedford K type which Bedford brought out in the late 30’s/early 40’s whilst the later Pocketoys used the Bedford RL model, more commonly known as the ‘Big Bedford’.

Bedford truck – which dominated the series throughout its production with a range of colourful plastic cabs and chassis onto which was mounted an array of various tinplate ‘boxes’. Early Pocketoy lorries were based around the Bedford K type which Bedford brought out in the late 30’s/early 40’s whilst the later Pocketoys used the Bedford RL model, more commonly known as the ‘Big Bedford’.

Boys’ – was first used in 1955 and appeared on a multitude of toys including clockwork nursery rhyme figures, battery operated remote control cars, traditional tinplate vehicles and also on an increasing number of plastic toys and games made under license from various American companies. These toys featured many of the popular cartoon characters of the day including several Walt Disney favourites along with new television stars like Hanna-Barbera’s Fred Flintstone.

Boys’ – was first used in 1955 and appeared on a multitude of toys including clockwork nursery rhyme figures, battery operated remote control cars, traditional tinplate vehicles and also on an increasing number of plastic toys and games made under license from various American companies. These toys featured many of the popular cartoon characters of the day including several Walt Disney favourites along with new television stars like Hanna-Barbera’s Fred Flintstone.

companies to fill this void. One such company was the British Metal & Toy Manufacturers, which incorporated the letters from within its name to form the trademark – ‘BRIMTOY BRAND’, with the words ‘BRITISH MADE’ and a pictoral representation of Nelsons Column all within a roundal. Nothing could be more patriotic in those times !

companies to fill this void. One such company was the British Metal & Toy Manufacturers, which incorporated the letters from within its name to form the trademark – ‘BRIMTOY BRAND’, with the words ‘BRITISH MADE’ and a pictoral representation of Nelsons Column all within a roundal. Nothing could be more patriotic in those times ! These were however difficulties not just faced by BMTM, but by the toy industry as a whole, and unable to overcome several or all of these problems it was no surprise that many of the smaller companies at this time disappeared altogether.

These were however difficulties not just faced by BMTM, but by the toy industry as a whole, and unable to overcome several or all of these problems it was no surprise that many of the smaller companies at this time disappeared altogether. British manufacturers, the demand from which would dwarf the home markets which had kept the industry going. The boom which followed was short lived and lasted just two years ! Consumer expenditure rose by 21% between 1918 – 19 and the removal of wartime controls in the spring of 1919 gave it further impetus. But productive capacity could not keep pace with demand and as a result prices rose faster than output, which in turn pushed up wages and thus costs. By the middle of 1921 Britain was in the grip of severe depression with c2,400,000 workers unemployed. This inevitably took its toll on the toy industry with hundreds of companies closing their doors. One such company, despite having a turnover of £75,000 in 1919 and 1920, was the British Metal & Toy Manufacturers which was liquidated in 1921.

British manufacturers, the demand from which would dwarf the home markets which had kept the industry going. The boom which followed was short lived and lasted just two years ! Consumer expenditure rose by 21% between 1918 – 19 and the removal of wartime controls in the spring of 1919 gave it further impetus. But productive capacity could not keep pace with demand and as a result prices rose faster than output, which in turn pushed up wages and thus costs. By the middle of 1921 Britain was in the grip of severe depression with c2,400,000 workers unemployed. This inevitably took its toll on the toy industry with hundreds of companies closing their doors. One such company, despite having a turnover of £75,000 in 1919 and 1920, was the British Metal & Toy Manufacturers which was liquidated in 1921. there were, it has to be said, many others who opened up to take advantage of the upturn in trade which took place after 1923. One such company which was founded in 1923 was Brimtoy Ltd., who included amongst its directors many from the now defunct BMTM and which continued, as before, in the production of tinplate toys. Their address was given as 133 Highbury Quadrant, Islington, London N5.

there were, it has to be said, many others who opened up to take advantage of the upturn in trade which took place after 1923. One such company which was founded in 1923 was Brimtoy Ltd., who included amongst its directors many from the now defunct BMTM and which continued, as before, in the production of tinplate toys. Their address was given as 133 Highbury Quadrant, Islington, London N5. 1919 launched with a capital of just £50. Because of his background Wells was able to make his own tooling and initially also did his own selling, so successfull was he that his company was destined to become a major force in the interwar years.

1919 launched with a capital of just £50. Because of his background Wells was able to make his own tooling and initially also did his own selling, so successfull was he that his company was destined to become a major force in the interwar years. Wells operated from the ‘Progress Works’, 90 Somers Road, Walthamstow, in North London and their well known Wells ‘O’ London trademark first made is appearance in 1924.

Wells operated from the ‘Progress Works’, 90 Somers Road, Walthamstow, in North London and their well known Wells ‘O’ London trademark first made is appearance in 1924.

clockwork motors were incorporated into the models to add movement and even greater sense of realism to the toy.

clockwork motors were incorporated into the models to add movement and even greater sense of realism to the toy. dating back to the mid 1800’s with the likes of the PHILADELPHIA TIN TOY MANF., FALLOWS, BERGMANN, IVES and BUCKMAN this reputable list was added to by the likes of UNIQUE ART, STRAUSS, CHEIN, WOLVERINE and MARX.

dating back to the mid 1800’s with the likes of the PHILADELPHIA TIN TOY MANF., FALLOWS, BERGMANN, IVES and BUCKMAN this reputable list was added to by the likes of UNIQUE ART, STRAUSS, CHEIN, WOLVERINE and MARX. shape of Japan. Japan had been a major producer of tin toys for as long as the Europeans but it was not until the late 1940’s and ’50’s and even into the early 1960’s that production reached its height with the introduction of many new novelties. Not just wind-up and friction drive motors but Japanese tin plate toys were also incorporating battery power not simply to drive the toy but also to provide lights and sounds.

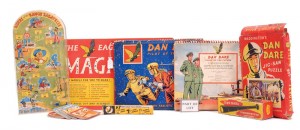

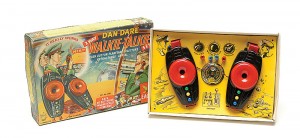

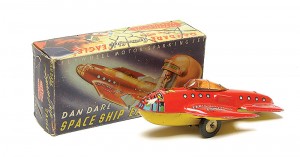

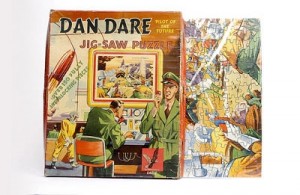

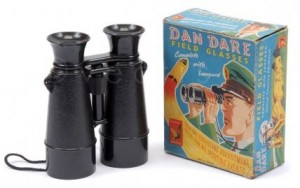

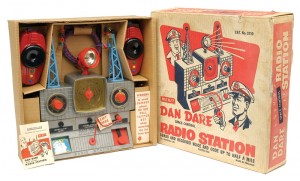

shape of Japan. Japan had been a major producer of tin toys for as long as the Europeans but it was not until the late 1940’s and ’50’s and even into the early 1960’s that production reached its height with the introduction of many new novelties. Not just wind-up and friction drive motors but Japanese tin plate toys were also incorporating battery power not simply to drive the toy but also to provide lights and sounds.![d.dare-radio-300x181[1]](http://rodgersantiques.co.uk/wp-content/uploads/2009/12/d.dare-radio-300x1811.jpg)

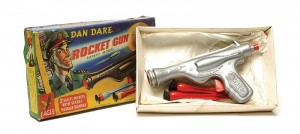

Dan Dare was the chief pilot of the Interplanet Space Fleet and typical of the heroes of that era was bound by a sense of honour, never lied and would rather die than break his word …. in other words an all round good egg ! Together with Digby his stout (in more senses than one) batman they constantly battled with The Mekon in his attempt to conquer the Earth.

Dan Dare was the chief pilot of the Interplanet Space Fleet and typical of the heroes of that era was bound by a sense of honour, never lied and would rather die than break his word …. in other words an all round good egg ! Together with Digby his stout (in more senses than one) batman they constantly battled with The Mekon in his attempt to conquer the Earth.