Tri-ang Toys / Triang Pressed Steel Toys / Triang Pressed Steel Vehicles : Large-Scale

An Introduction to the Range of Large Scale Pressed Steel Commercials from Tri-ang Toys :

This post is meant as an introduction to the Tri-ang range of large-scale pressed steel lorries which were produced from the early 1930’s through to the demise of Tri-ang in the mid-1970’s. Please be aware that dates given for the vehice ranges are approximate and intended only as a guide.

During this time frame nine different ranges of lorry were produced along with trains and cranes although it should be mentioned that up to the mid 1950’s most of the trains produced were made from wood and between 1957 and 1970 Tri-ang brought out their iconic pressed steel buses which I may well return to at a later date.

1930 – 1937 saw Tri-angs first metal lorries range being produced, these were an open cab type vehicle with a long bonnet, radiators were either silver or black with thin metal wheels fitted with thin rubber tyres. Best described as a toy and not a model, relatively crude and nieve in their design and manufacture yet having said all that are today seen by many as being full of charm and character.

were an open cab type vehicle with a long bonnet, radiators were either silver or black with thin metal wheels fitted with thin rubber tyres. Best described as a toy and not a model, relatively crude and nieve in their design and manufacture yet having said all that are today seen by many as being full of charm and character.

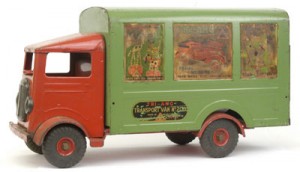

This first early series of metal lorries included a tipper truck, milk lorry and breakdown truck together with the timber lorry pictured above. To compliment the lorries a series of box vans in different liveries was also produced which included amongst others the Carter Paterson van shown opposite.

This first early series of metal lorries included a tipper truck, milk lorry and breakdown truck together with the timber lorry pictured above. To compliment the lorries a series of box vans in different liveries was also produced which included amongst others the Carter Paterson van shown opposite.

1937 – 1956 saw the arrival of the Bedford range of Tri-ang pressed steel lorries, so called as they were made to resemble the Bedford trucks of the day.

The range of vehicles produced was similar to the previous metal lorries range but now featured an enclosed cab and came complete with a load where appropriate.

The ‘Bedfords’ could have any of three different radiator grills fitted, a standard unpainted one or ones painted in either cream or black. As a rough rule of thumb the pre-war models came with thin metal disc wheels and tyres which were replaced post war with thick rubber tyres but as always there was some overlap as there were some Tri-ang vehicles produced even in 1950 with metal disc wheels. By far an easier way of identifying a pre-war Bedford series is to check the underside of its chassis. Pre-war this would be constructed using a single sheet of steel whereas post war versions would see the chassis having circular and/or rectangular sections cut out of it in order to save metal. Tyres on the Bedford series of lorries were always 7cm dia. except on the breakdown lorry where the diameter was increased to 9cm. (3.5″).

Bedford series is to check the underside of its chassis. Pre-war this would be constructed using a single sheet of steel whereas post war versions would see the chassis having circular and/or rectangular sections cut out of it in order to save metal. Tyres on the Bedford series of lorries were always 7cm dia. except on the breakdown lorry where the diameter was increased to 9cm. (3.5″).

1948 – 1957 saw Tri-ang bring out their third series of pressed steel lorries known as the ‘200’ series. In this series the lorries adopted the new square shaped forward control type cab. Initially three models, two tipping/builders lorries and a transport van made up the series with a petrol tanker and mobile crane being added later. Of the two tipping lorries one was manufactured with ‘remote control’ steering, this had a raised steering wheel at the rear and steered the front wheels via a universal coupling.

1948 – 1957 saw Tri-ang bring out their third series of pressed steel lorries known as the ‘200’ series. In this series the lorries adopted the new square shaped forward control type cab. Initially three models, two tipping/builders lorries and a transport van made up the series with a petrol tanker and mobile crane being added later. Of the two tipping lorries one was manufactured with ‘remote control’ steering, this had a raised steering wheel at the rear and steered the front wheels via a universal coupling.

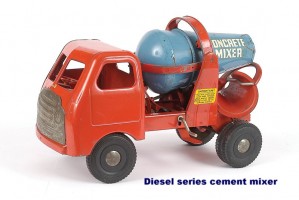

1955 – 1960 brought about Tri-ang’s ‘Diesel’ series. This Tri-ang series although smaller than the 200 series carried a much larger range of vehicles. Initially the series began with just two lorries, the first was the usual tipper lorry but the second was a much more unusual working cement mixer lorry which had a drum which was linked to the lorry axle and thus revolved as the lorry moved forwards. The drum could also be tipped to allow its load to be emptied through a rear

1955 – 1960 brought about Tri-ang’s ‘Diesel’ series. This Tri-ang series although smaller than the 200 series carried a much larger range of vehicles. Initially the series began with just two lorries, the first was the usual tipper lorry but the second was a much more unusual working cement mixer lorry which had a drum which was linked to the lorry axle and thus revolved as the lorry moved forwards. The drum could also be tipped to allow its load to be emptied through a rear  trough just as on an actual cement mixer.

trough just as on an actual cement mixer.

These lorries were in turn followed by the Express Delivery Lorry, a Breakdown Services lorry which had a working crane jib fitted with hoist along with a toolbox with tools. The range also included a Farm lorry complete with its load of plastic pigs, a Milk wagon with milk churns, a Petrol Tanker with ‘Shell’ logo  to tank sides and rear and a Fire Engine complete with bell, rotating and extending ladder, fireman and working hose. The Diesel series also included several six-wheeled which included amongst others Military lorries and a Side-Tipping Ballast Truck. Around 1957 Triang also added several articulated lorries into the Diesel range which included a low loader with excavator and a car transporter.

to tank sides and rear and a Fire Engine complete with bell, rotating and extending ladder, fireman and working hose. The Diesel series also included several six-wheeled which included amongst others Military lorries and a Side-Tipping Ballast Truck. Around 1957 Triang also added several articulated lorries into the Diesel range which included a low loader with excavator and a car transporter.

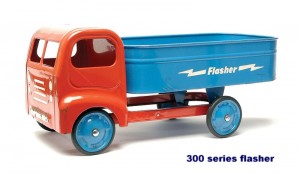

1957 – 1963, as Triang lauched its articulated lorries in the Diesel series it dropped the ‘200’ series lorries and launched a new ‘300’ series (Still with me ?). Gone were the square cab shaped 200’s to be replaced by a more rounded cab, similar to the Diesel in some respects but now with front protruding wheel arches which reflected a more modern ’50’s styling.

1957 – 1963, as Triang lauched its articulated lorries in the Diesel series it dropped the ‘200’ series lorries and launched a new ‘300’ series (Still with me ?). Gone were the square cab shaped 200’s to be replaced by a more rounded cab, similar to the Diesel in some respects but now with front protruding wheel arches which reflected a more modern ’50’s styling.

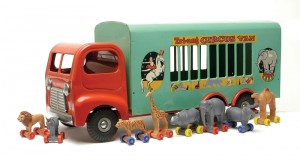

The ‘300’ series carried the same body styles to that of the ‘200’ series but added to the range was now a mobile cafeteria van with side opening canopies and came complete with various plastic items including a jug and drinking glasses ! Later models included a horse transporter which came with two wooden horses, later changed to plastic and several six-wheel vehicles amongst which was a circus van together with various animals and a long distance transport van.

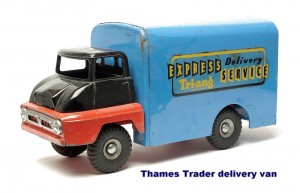

1959 – 1966 saw Tri-ang attempting to keep pace with the changing face of road transport of the day with a range of commercial vehicles which mirrored their modern day counterparts thus the Thames Trader range was launched.

1959 – 1966 saw Tri-ang attempting to keep pace with the changing face of road transport of the day with a range of commercial vehicles which mirrored their modern day counterparts thus the Thames Trader range was launched.

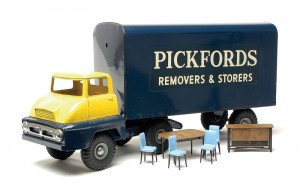

Fifteen vehicles made up the Thames Trader range and included all the old favourites such as the tipper lorry, farm truck, milk lorry, delivery van, fire engine, breakdown lorry etc.etc. Also included in the range were several articulated lorries, the car transporter, low loader, rocket transporter, removals van, flat truck, open truck and petrol tanker.

Interestingly Tri-ang also added working headlights into some models which used small torch bulbs powered by batteries housed underneath the chassis and operated by a simple push-in switch located on the side of the chassis behind the cab.

1958 – 1967 was the time frame for Tri-ang’s Junior Series, launched with just seven commercial vehicles making up the range they always remind me of the big American trucks of the ’60’s with their high cabs and large radiator grills. The initial seven comprised the farm truck, tip lorry, petrol tanker, milk lorry, delivery van, open back truck and a breakdown lorry. All seven carried a header board sited on top of the cab with the Tri-ang name prominant.

carried a header board sited on top of the cab with the Tri-ang name prominant.

A host of other commercials were added to the series over time including some more unusual ones such as the army transport van with canvas tilt, a similar raf van, a police van, mobile shop van, musical ice cream van, a radar control truck and an airport crash tender. All in all over twenty different lorries were to make up the Junior series.

There were now three commercial ranges running simultaneously :

The smaller Junior Series / The medium Thames Trader Series / The larger ‘300’ Series.

1962 – 1966 saw Tri-ang update the tiring ‘300’ series with the addition of plastic bumpers and lights, side mirrors, air horns, plastic windows and windscreen wipers all under the Regal Roadster series banner. Colours were now in metallic paint rather than the usual red, blue and turquoise enamels and the vehicles now had grey plastic wheels and for novelty value a ‘clicker’ mechanism was fitted to the front axle of the commercial which made a noise as the lorry was pushed along.

1962 – 1966 saw Tri-ang update the tiring ‘300’ series with the addition of plastic bumpers and lights, side mirrors, air horns, plastic windows and windscreen wipers all under the Regal Roadster series banner. Colours were now in metallic paint rather than the usual red, blue and turquoise enamels and the vehicles now had grey plastic wheels and for novelty value a ‘clicker’ mechanism was fitted to the front axle of the commercial which made a noise as the lorry was pushed along.

All three of the Tri-ang commercial vehicle ranges that is the Junior, Thames  Trader and Regal Roadster series all met their end at about the same time. Around 1966 they were dropped for a new Tri-ang range of vehicles which was the Hi-Way series and branded as ‘modern trucks for modern children’. This series would continue through to the demise of Tri-ang in 1973. This Hi-Way series was perhaps the worse that Tri-ang put out, garish in its looks and lacking in appeal the trucks were smaller than even the Junior commercials and comprised more plastic in their make-up yet gone were the plastic extras that proved so popular on the Regal Roadsters. A sad end to a once mighty toy maker.

Trader and Regal Roadster series all met their end at about the same time. Around 1966 they were dropped for a new Tri-ang range of vehicles which was the Hi-Way series and branded as ‘modern trucks for modern children’. This series would continue through to the demise of Tri-ang in 1973. This Hi-Way series was perhaps the worse that Tri-ang put out, garish in its looks and lacking in appeal the trucks were smaller than even the Junior commercials and comprised more plastic in their make-up yet gone were the plastic extras that proved so popular on the Regal Roadsters. A sad end to a once mighty toy maker.

a picture gallery of some of the rarer vehicles :

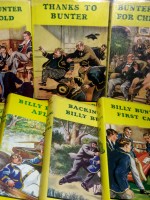

So began many a tale of a hero of mine good old William George Bunter of Greyfriars School.

So began many a tale of a hero of mine good old William George Bunter of Greyfriars School. been for publisher Charles Skilton who commissioned Charles Hamilton to write a series of books around Bunters adventures and those of the ‘Famous Five’ (no not the Enid Blyton ones these were the original ones, Wharton, Cherry, Bull, Newton and Hurree Jamset Ram Singh or Inky to his friends) at a fictitious private school in Kent …… Greyfriars.

been for publisher Charles Skilton who commissioned Charles Hamilton to write a series of books around Bunters adventures and those of the ‘Famous Five’ (no not the Enid Blyton ones these were the original ones, Wharton, Cherry, Bull, Newton and Hurree Jamset Ram Singh or Inky to his friends) at a fictitious private school in Kent …… Greyfriars.

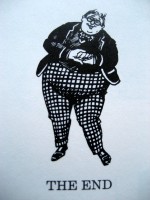

one is to avoid work of any description indeed he will often spend twice as long trying to avoid it as doing it in the first place ! Instead he prefers to laze in a comfy armchair in front of a blazing fire eating a chunk of toffee .. for that is Bunters other concern .. food. By any standards Bunter is big, no lets be honest Bunter is fat, and his thoughts are almost always centred on feeding the inner Bunter. Bunters greediness knows no bounds, sticky buns and cake he can demolish at a sitting but its perhaps jam that has the ability to draw him like a magnet. Despite never having any money himself, although he is always expecting his infamous Postal Order to arrive, Bunter is a master scrounger up and down the Remove of anything from the odd copper or two to a sixpenny piece and in some exceptional cases the odd half-a-crown, anything with which to buy some sticky sweetmeats from the tuck shop and if all else fails he is quite capable of helping himself to comestables from other boys study cupboards ! all without a though for the rightful owner, inevitably Bunter is found out

one is to avoid work of any description indeed he will often spend twice as long trying to avoid it as doing it in the first place ! Instead he prefers to laze in a comfy armchair in front of a blazing fire eating a chunk of toffee .. for that is Bunters other concern .. food. By any standards Bunter is big, no lets be honest Bunter is fat, and his thoughts are almost always centred on feeding the inner Bunter. Bunters greediness knows no bounds, sticky buns and cake he can demolish at a sitting but its perhaps jam that has the ability to draw him like a magnet. Despite never having any money himself, although he is always expecting his infamous Postal Order to arrive, Bunter is a master scrounger up and down the Remove of anything from the odd copper or two to a sixpenny piece and in some exceptional cases the odd half-a-crown, anything with which to buy some sticky sweetmeats from the tuck shop and if all else fails he is quite capable of helping himself to comestables from other boys study cupboards ! all without a though for the rightful owner, inevitably Bunter is found out  whereupon its whops from Quelch – Swipe ! .. ‘Yarooooh’, Swipe ! .. ‘Oh ! Ooooh !’, Swipe, Swipe, SWIPE ! .. ‘ Yow – Ow – WHOOOOOOOP !’ or a booting from his fellow Removites – ‘I- I say, you fellows, Yow-wow, Beasts, Oh-lor’ !’ neither of which has any effect on him except in the short term.

whereupon its whops from Quelch – Swipe ! .. ‘Yarooooh’, Swipe ! .. ‘Oh ! Ooooh !’, Swipe, Swipe, SWIPE ! .. ‘ Yow – Ow – WHOOOOOOOP !’ or a booting from his fellow Removites – ‘I- I say, you fellows, Yow-wow, Beasts, Oh-lor’ !’ neither of which has any effect on him except in the short term.

any Dinky lorry for reference at this point where the cab and chassis form one casting). When this is the case our hero draughtsman comes to our aid and modifies the design such that one of its two sections will now have further parts within it which will slide out sideways so as to allow the casting to be ejected from the mould. (pause for a fanfare of trumpets for the drawing office !).

any Dinky lorry for reference at this point where the cab and chassis form one casting). When this is the case our hero draughtsman comes to our aid and modifies the design such that one of its two sections will now have further parts within it which will slide out sideways so as to allow the casting to be ejected from the mould. (pause for a fanfare of trumpets for the drawing office !). case of the radiator grille, headlights or front and rear bumpers, in others its a colour flash to a rear wing but this now requires the use of a hand spray gun. It also involves the use of model ‘masks’ which will allow the application of the second colour, say aluminium for headlights, being applied where it is needed without contaminating other parts of the model. These hand gun stations are located along a conveyor table fitted with miniature spraying booths and the masks used will vary according to the needs of the particular model. Baking follows again to harden the enamel and then the model is ready for final assembly.

case of the radiator grille, headlights or front and rear bumpers, in others its a colour flash to a rear wing but this now requires the use of a hand spray gun. It also involves the use of model ‘masks’ which will allow the application of the second colour, say aluminium for headlights, being applied where it is needed without contaminating other parts of the model. These hand gun stations are located along a conveyor table fitted with miniature spraying booths and the masks used will vary according to the needs of the particular model. Baking follows again to harden the enamel and then the model is ready for final assembly.